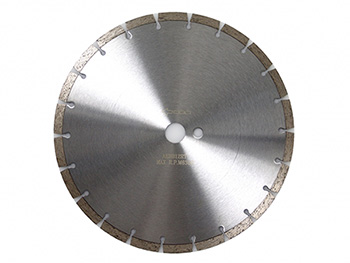

Masonry Diamond Saw Blades

No matter what architectural project you are in, qualified diamond saw blades take great importance in terms of safety and efficient. We are professional in diamond cutting tool manufacturing, and our diamond blades are highly qualified, choose our products for better safety and efficient.

Vast majority of our diamond blade, diamond wire saw and other diamond tools meet European EN13236 safety requirement. We built our blades applying premium saw cores and GE grinding diamonds for better performance. Our blades features better cutting speed, cutting depth and durability, while at a fair price.

Concrete

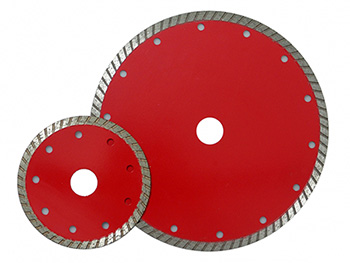

Ceramic

Marble

Granite

Ceramic Tiles

- Specially 45 degree preferably arranged diamond grants excellent sharpness of the blades, which means high efficient;

- Promote durability by properly arrange diamonds;

- We provide detailed abrasive ratio test data; we can help our customers design their suitable blades;

- OEM service, including printing, packaging and designing;

- Hard and abrasive resistant, which makes it able for cutting harder materials;

- Sharp blades grants better performance and efficient;

- Cost-effective due to diamond blade’s efficient, though it cost a bit more than common blades;

- Able for large scale cutting;

- Good thermal conductivity grants better cooling performance;

- Low thermal expansion coefficient, low blade shape change during cutting.

Shenzhen Idimas Holding Co., Ltd. provides highly qualified diamond tools for cutting, grinding and drilling. For the past years, we’ve been applying advanced technologies and devices, and premium materials for diamond tool manufacturing. Our diamond tools include saw blades, grinding tools, core bits, etc. Our diamond cutting tools are able for wet and dry cuttings on various materials, including concrete, ceramic, marble, asphalt, steel, wood, etc.